Molecular Surface Engineering (MSE)

MSE-technology opens a new dimension in the molecular design of surfaces. Specific structures and characteristic features of surfaces for special use can be adjusted on a chemical-molecular basis.

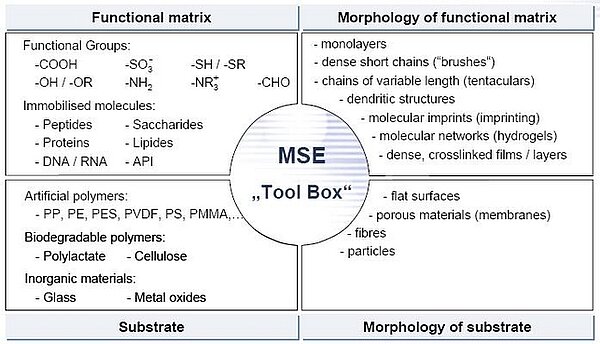

A wide range of combinations from morphology, source material (substrate) and functional groups is possible. No matter if inorganic polymers like glass, natural polymers like cellulose, or artificial polymers like polypropylene, if planar or porous – via spacer nearly any functionality can be covalently bound to the substrates, without influencing their physical characteristics (e.g. their autofluorescence and mechanical stability).

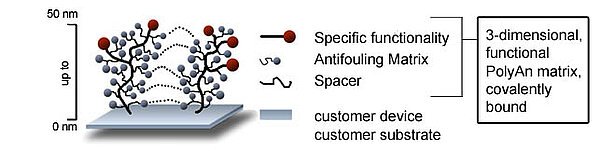

The characteristics of surfaces that have been functionalized using Molecular Surface Engineering are solely specified by the functional matrix. Thus, the mechanical characteristics of the source material are combined with the new biological-chemical characteristics of the surface. The surface can contain both simple functional groups such as –COOH or –NH2 and complex peptide or DNA molecules. The morphology of the functional matrix is alterable, and that is a core competence of PolyAn: Not only “brushes”, “tentacles” or dendritic structures are possible, but also diagonally integrated layers, so that the result is a loading density that can be narrowly fine-tuned to the specific application.